How Custom Heating Solutions Boost Experimental Stability, Repeatability, and Data Quality

Accurate scientific results depend on more than instrumentation alone—precise thermal control is the backbone of reliable experimentation. Across laboratories and research facilities, new precision heating technologies are helping scientists improve accuracy, repeatability, and confidence in their data.

From analytical instruments to test and measurement systems, advances in laboratory heating solutions are enabling more precise temperature control, consistent experimental conditions, and reliable, repeatable test results.

To ensure meaningful test results and achieve performance goals, however, it is essential to align priorities and expectations early in the design phase. Whatever the goals are—tight temperature control, rapid thermal response, long-term stability, etc.—aligning priorities ensures optimal heater design.

Why Is Precise Temperature Control Important in Scientific Experiments?

Precise temperature control ensures experiments are conducted under consistent conditions. Many scientific processes are temperature-sensitive, and even small variations can introduce errors, reduce reproducibility, or compromise data integrity.

BackerHotwatt partners with scientific instrument manufacturers, engineers, and R&D teams early in the design process to create a diverse range of laboratory, analytical, and test and measurement heating solutions. Our approach is not “one size fits all.” Our customers’ design challenges often require more than standard, off-the-shelf heaters to achieve specific instrument design and performance goals.

The Role of Custom Heating Solutions in Research Accuracy

Off-the-shelf heaters often do not meet the unique requirements ofadvanced research applications. Customheaters for scientific instrumentsallow engineers and researchers to specify:

- Watt density

- Heater geometry and size

- Material selection

- Lead configuration and mounting

Tailored solutions ensure that heat is applied exactly where and how it’s needed, a critical factor in achieving consistent and repeatable results.

How to Achieve Precision, Performance, and Speed at Any Scale

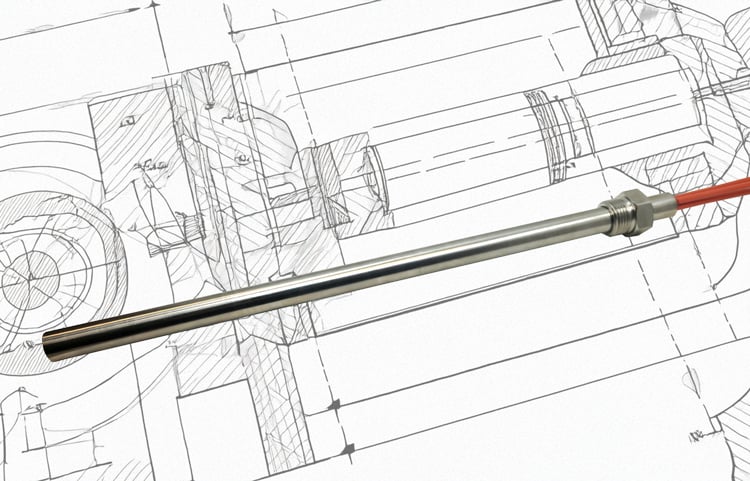

Working closely with customers’ engineers and R&D teams, Hotwatt has developed an impressive portfolio of heaters—cartridge, foil, ceramic, tubular, and more—that help our manufacturing partners achieve precision, performance, and speed at any scale.

Over the years, we have been asked a variety of questions about ourcustom heating solutions and how our collaborative process works.

These include:

1. How do heating technologies affect experimental accuracy?

Many scientific experiments are highly sensitive to even small temperature fluctuations. Variations of just a few degrees can alter chemical reactions, affect material behavior, or compromise sensor calibration. Modern heating technologies for scientific instruments are designed to:

-

- Maintain stable operating temperatures

- Minimize thermal drift and fluctuations that can alter chemical reactions, sensor readings, or material behavior

- Reduce environmental interference

- Support reliable, reproducible experimental results

2. Are custom heaters better than standard heaters for laboratory applications?

Custom heaters are often better for laboratory applications because they are designed specifically for the instrument’s geometry, wattage requirements, and operating environment. This customization improves thermal efficiency and temperature accuracy.

3. What is thermal drift and how can it be reduced?

Thermal drift is the gradual change in temperature over time that affects instrument performance. It can be reduced by using precision heaters with stable output, proper insulation, and heater placement close to critical components.

4. How can I integrate precision heating into my experiment design?

Precision heating should be considered early in experiment or instrument design.Integrating heaters near critical zones and working with heating specialists ensures optimal thermal performance and long-term reliability.

5. How do fast-response heaters improve experimental control?

Fast-response heaters reach target temperatures quickly and reduce overshoot. This allows experiments to stabilize faster and maintain precise control during temperature changes or cycling.

6. Can precision heating reduce experimental errors?

Yes. Precision heating reduces experimental errors by minimizing temperature gradients, preventing condensation, and stabilizing sensitive components, all of which help ensure accurate measurements.

How to Leverage Heating Technologies in Your Experiments

To maximize the impact of modern heating solutions, researchers can:

- Position heaters close to critical zones to reduce heat loss and thermal gradients.

- Select responsive heating elements for precise temperature transitions.

- Integrate thermal control early in the instrument design process, rather than as an afterthought.

- Collaborate with heating experts to optimize performance for a specific application.

These strategies help ensure that temperature control and accuracy in experiments remain stable throughout testing cycles.Backer Hotwatt’s expertise in engineering precise, reliable heating solutions is valued by customers across a variety of scientific endeavors.

Compact, Integrated Heating Solutions for Optimal Instrument Design and Accurate Results

Tough heating challenges demand more than off-the-shelf solutions. AtBacker Hotwatt, we partner with manufacturers, engineers, and R&D teams to tackle unique application thermal needs—whether it’s precise, compact, or built for demanding environments.

Our collaborative approach means rapid prototyping, tailored heater design, and seamless integration from concept to production. Whether you need one custom prototype or 1,000 heaters for production, Hotwatt’s design and manufacturing agility make it possible to iterate faster, optimize performance, and bring innovation to market sooner.

Explore our capabilities here or connect with an engineer to talk about your next project.