Outlining the Steps to Gauge the Life of Your Cartridge Heater

Cartridge heaters are essential components in various OEM industrial processes. Low-, medium-, and high-watt density heaters provide an efficient, reliable heat source for dies, platens, and a variety of other types of processing equipment. The size, sheath, leads, terminals, wattage, and voltage can be adapted to meet your heating requirement needs.

As part of the design and planning process, estimating the life expectancy of a cartridge heater is crucial for optimizing performance, enhancing longevity, and minimizing downtime. Understanding the key factors and considerations that determine cartridge heater life help to accurately assess and extend the lifespan of your heaters.

Fundamentals of Cartridge Heaters

Cartridge heaters are manufactured by inserting chrome wire heating coils in holes formed in ceramic tubes. Pure magnesium oxide filler is vibrated into the holes housing the heating coils to allow maximum heat transfer to the stainless-steel sheath. The heater then has a heliarc-welded end cap inserted on the bottom of the heater and insulated leads are installed.

A variety of factors influence cartridge heater life, including:

Operating Temperature: Cartridge heaters exposed to higher temperatures generally have a shorter lifespan. Monitoring and controlling the operating temperature within the recommended range is essential for maximizing heater life.

Voltage and Power Density: Excessive voltage or power density can accelerate wear and tear on the resistance wire, leading to premature failure. Ensuring the cartridge heater operates within the specified voltage and power density limits is important.

Environment and Contaminants: Harsh operating environments, such as corrosive atmospheres or exposure to contaminants, can adversely affect cartridge heater life. Implementing proper shielding and protection measures can mitigate these risks.

Duty Cycle and Cycling Frequency: Cartridge heaters subjected to frequent cycling may experience thermal stress, impacting their longevity. Understanding the duty cycle and optimizing cycling frequency can help extend the heater’s operational life.

Material: The choice of materials for the sheath and insulator significantly influences cartridge heater performance. Selecting the appropriate materials based on the application requirements and environmental conditions is crucial for longevity.

Estimating Cartridge Heater Life

A few basics to keep in mind when considering heater life are the manufacturer’s specifications, visual inspection, and monitoring resistance. The manufacturer’s specs often provide information on anticipated lifespan under specific operating conditions. Inspecting the heater’s condition periodically can reveal signs of wear, damage, or corrosion that can be addressed proactively. Regularly measuring the resistance of the cartridge heater is also important, to catch any significant deviation from the initial resistance which may indicate degradation.

The steps below outline how to determine cartridge heater life.

- Record block operating temperature.

- Determine heater density-watts/square inch.

- Determine heater fit in block.

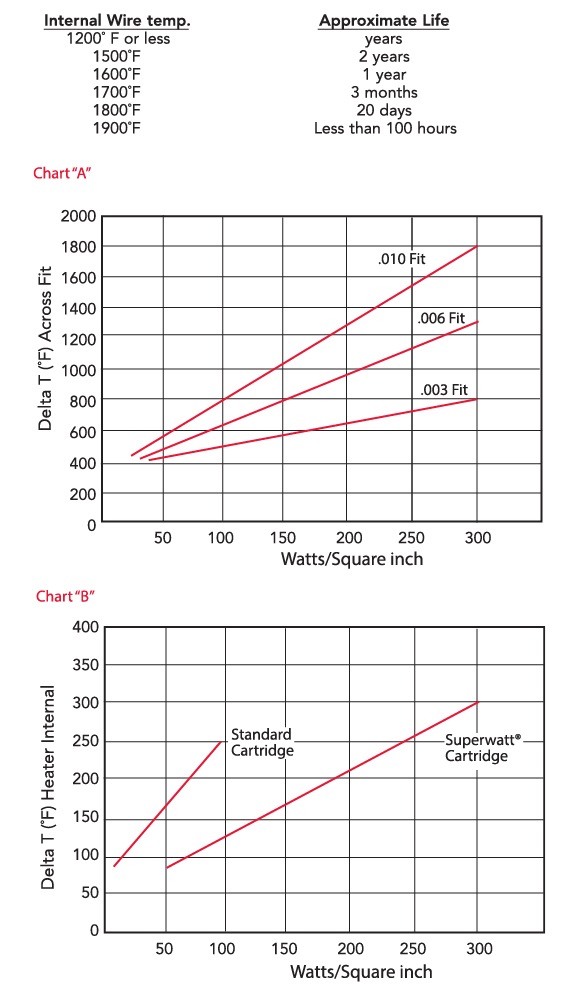

- From Chart A, determine the Delta T (temperature drop) across block hole.

- From Chart B, determine the heater internal Delta T (temperature drop).

- Add steps 1, 4, and 5 to determine approximate heater internal wire temperature.

- Figure estimated heater life from internal wire temperature based on the following tables.

Tables for Estimated Heater Life Based on Internal Wire Temperature:

Optimizing Heater Performance and Longevity

Estimating and extending cartridge heater life requires adhering to operating specifications, proactive monitoring, and preventive maintenance. By understanding the key factors impacting their lifespan and implementing proper care, OEMs can optimize the performance of cartridge heaters and minimize unplanned downtime.

As OEMs address critical design criteria, the proper heating solution is key to the overall success of their output. Backer Hotwatt is an industry leader dedicated to the design and manufacture of resistive heating elements for OEMs. By engaging with Backer Hotwatt early in the design phase, you will benefit from our extensive industry knowledge. Working together, we will develop well-defined thermal device requirements and a custom heater solution designed to best suit your application needs.

How can we help you with your next heating project? Contact an engineer today to set up an exploration consultation. We look forward to helping you soon.