In additive manufacturing, heat matters. A uniform heat source is required to deliver consistent heat to the heating block. The heating block transfers energy to the nozzle and enables the media to be dispensed. Maintaining an accurate and uniform heat at the nozzle tip can be a challenge. The best way to ensure consistent heat across the nozzle is to select the proper nozzle and pair it with a quality cartridge heater.

While brass is the most popular material chosen for printer nozzles, there are other options to consider. Brass is inexpensive and has excellent conductive properties, but it is soft and will take damage over time. Stainless steel is a great alternative, but it doesn't heat as efficiently as brass. The best performance nozzles are a composite design consisting of a brass neck and a ruby tip. This delivers an optimum heat profile paired with rugged performance.

Cartridge Heaters are the most reliable solution for delivering stable and repeatable heat to the nozzle. However, most cartridge heaters exhibit non-uniform heat profiles across the length of the cartridge. The tip may be lower in temperature than the center point for instance. At Backer Hotwatt, we now have an innovative solution to this common dilemma.

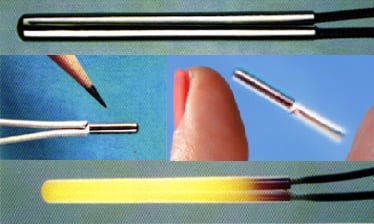

The SunRod mini cartridge delivers consistent heat from front to back. This unique heat profile paired with a split-sheath housing enables the cartridge heater to sit tightly, resulting in excellent heat transfer to the heater block. This design feature makes the SunRod a superb choice for additive manufacturing applications. The image below features our smallest SunRod mini cartridge heater measuring 1/8" in diameter and 0.5" in length. Note the complete uniformity of the heat profile when voltage is applied.

The SunRod mini cartridge makes an exciting addition to the Backer Hotwatt portfolio. We invite you to request a free sample and tell us about your application. Upon review of your request we will send a free sample to all qualified inquiries.